Description

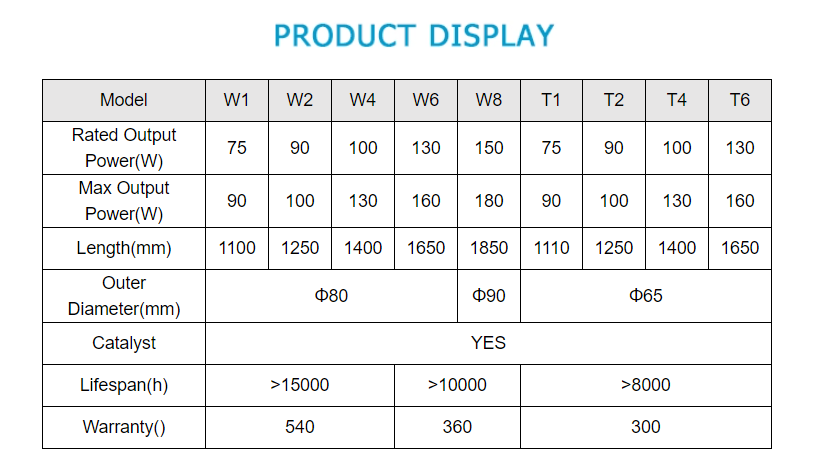

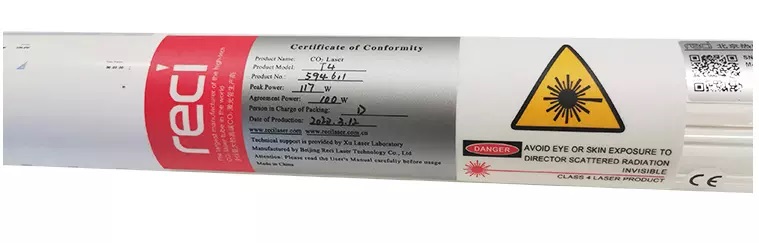

Reci upgrades and brings CO2 glass laser tube to 3.0 generation. Through the last ten years of development, the CO2 glass laser tube now develops to the third generation. The third generation of laser tube cancels the adjusting screws at both tube ends. Instead, the metal parts are made by a high-precise CNC machine. New firing technology is used to join metal parts and glass parts together directly. This new technology makes the high stability in W series laser tubes.

Q: How can I clean when the laser tube lens polluted?

A: Blow the lens surface obliquely with balloon. If the above no effect, user needs to remove the lens and use a cotton ball with a little alcohol to rotate the lens. No need too much alcohol, but the glue layer of the adhesive lens cannot be touched in case of gas inside escaping. The laser cannot be used till alcohol evaporating.

Q: How can I store the laser tubes when I do not use it?

A: The cooling liquid must run out in storage or transportation; The output must be covered with a dust-proof plastic wrap; The storage temperature should be kept between 2-40°C and the humidity between 10-60%.

Q: I want to customize the Fiber diameter. Can you do it?

A: Yes, we can do 20/30um for FSL1000 and 30/50um for FSC1500 and FSC2000. You can text me if you have other special requirements.

Additional information

| Voltage | 50W, 90W, 120W, 150W |

|---|

Reviews

There are no reviews yet.